Solutions and products for the future of intralogistics

Your partner for intralogistics, robotics, warehouse management and service

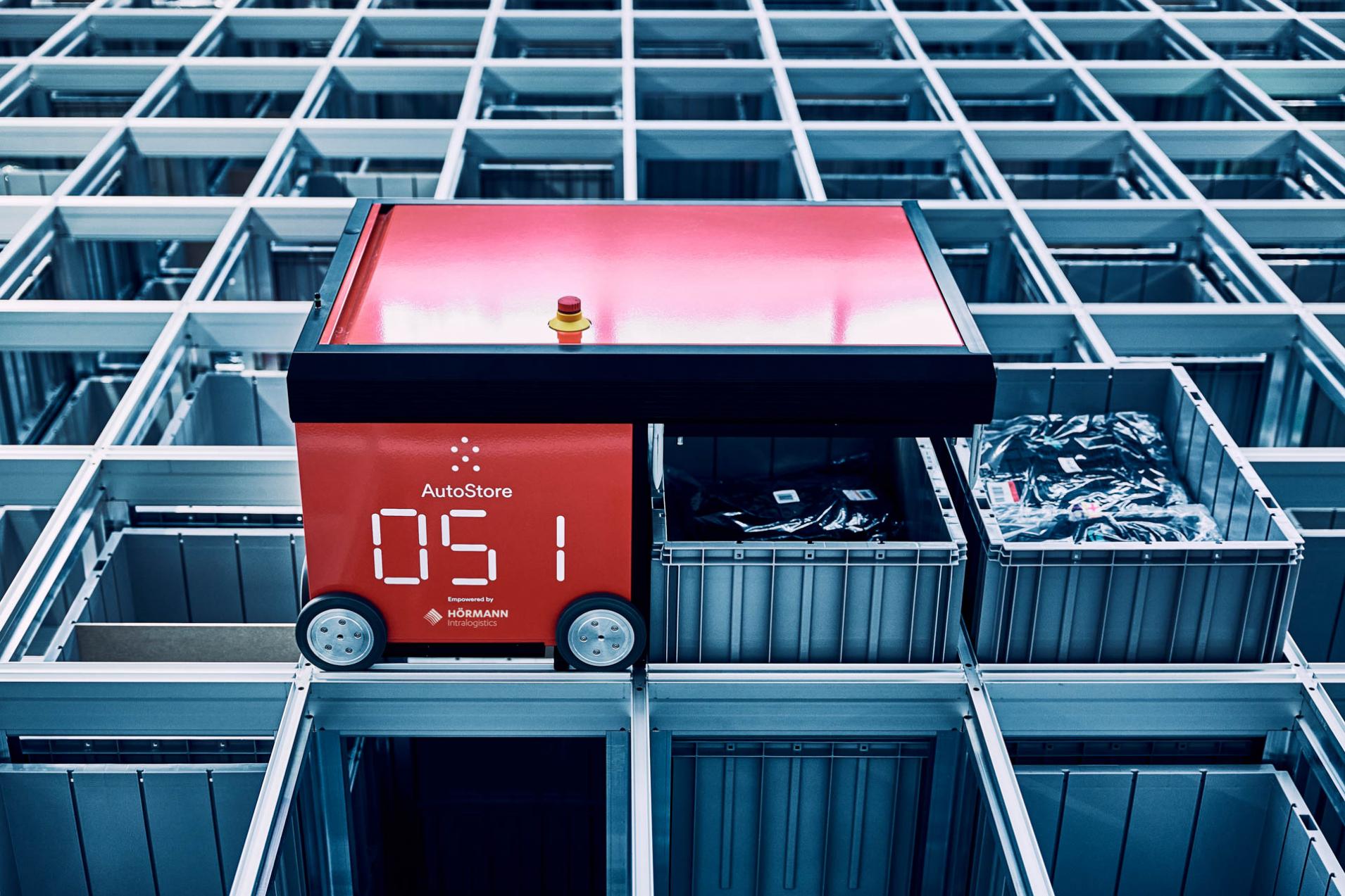

Along with renowned national and international partners, we develop innovative solutions and set new standards for intralogistics in terms of economic efficiency, performance and innovation.

Working to your advantage in five different areas

We are an attractive employment prospect for committed, performance-oriented people.

HÖRMANN Intralogistics - The Future of Intralogistics

Want to know more about HÖRMANN Intralogistics? Great! Just download our current brochure.